| U-bend tubes are widely used in heat-exchanger systems. Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential in strategically important and critical fields — nuclear and petrochemical machine building.

A tube-bending line, that was installed at Huawei in the end of 2007, allows to produce U-tubes

as per

such standards:

1. ASTM A688/A688M

2. ASTM A803/A803M

3. ASTM A556/A556M, ASME SA-556

4. ASME SA-688

At present Huawei has purchased the equipment for production of the following product range:

Steel Grades:

Carbon & Alloy |

Ferrite |

Austenite |

Duplex |

Super Duplex |

Ni-alloys |

Titanium |

A179

T11

T12

T22 |

TP410 |

TP 304 / 304L

TP 316 / 316L

TP 316Ti

TP 317 / 317L

TP 321

TP347 |

S31803

S32205 |

S32750

S32760 |

N06600

N08020

N00880

N08825

N08904 |

Gr.2 |

Tubes of other alloys and steel grades can be produced upon agreement.

Technical requirements

Straight tubes for bending:

ASTM/ASME SA 179; SA 213; ASTM B 163; ASTM B 729; ASTM B 407; ASTM B 423; ASTM A 789

U-bend Tubes:

-TEMA RCB 2.31 Standards of the Tubular Exchanger Manufacturers Association (9th edition).

-ASTM A688 Standard specification for welded tubes of austenite corrosion resistant steel grade designed for feed water boilers.

-ASTM B163 Standard technical requirements for tubes of nickel and nickel alloy for condensers and heat exchangers.

-Customer specifications.

|

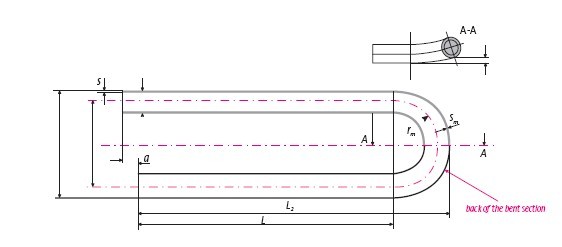

u bending |

BENDING RADIUS: from 1.5 OD to 1250 mm.

When ordering tubes with R≤1.5D it is necessary to agree precision of geometrics.

STRAIGHT TUBES MAXIMUM LENGTH (before bending): 26000 mm.

LEG LENGTH: min 1 meter, max 10.5 meters (for max R=1250 mm)

Note: other sizes are available upon agreement.

HEAT TREATMENT: Stress Relieved after U bending.

HYDROSTATIC TEST: maximum test pressure 600 bar, soaking 10 sec. with demineralized water. Compressed air cleaning after hydro-test.

Marking: before bending by marking machine all over the tube length (bent section after heat treatment without marking).

Marking is also possible after bending on the straight parts of U-bent tube.

Packaging: closed wooden boxes of corresponding dimensions for each tube length, radius, diameter, according to PO requirements or in bundles wrapped in polyethylene film with plastic clamping spacers on each tube.

|